ASSEMBLY

ASSEMBLY

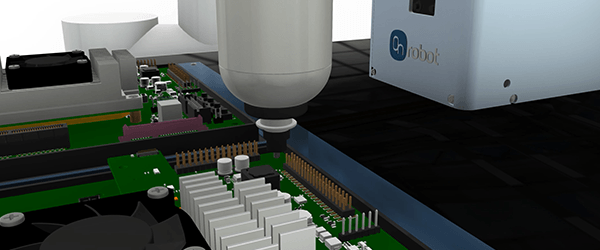

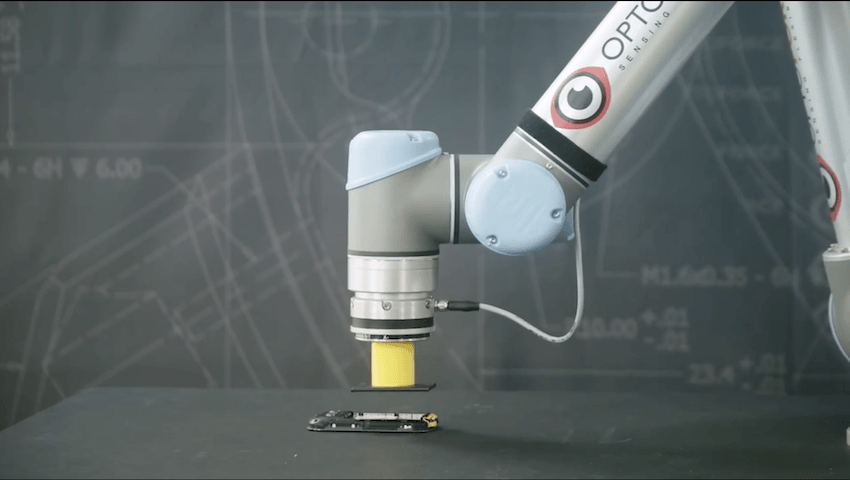

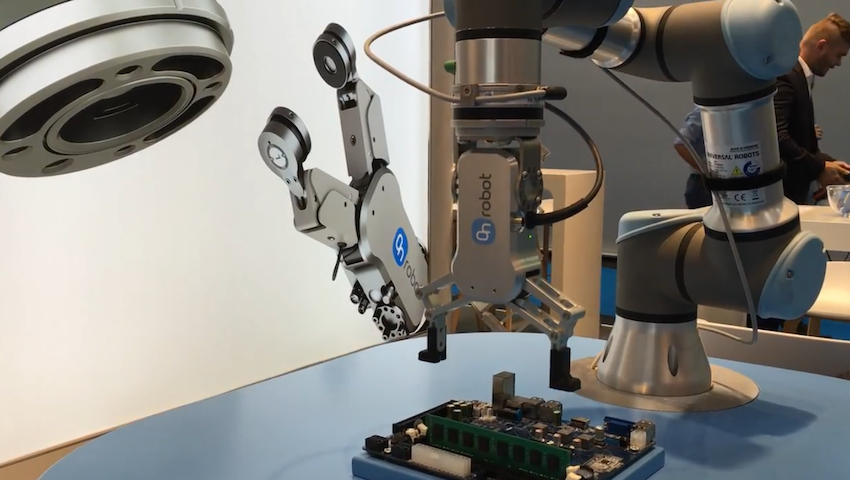

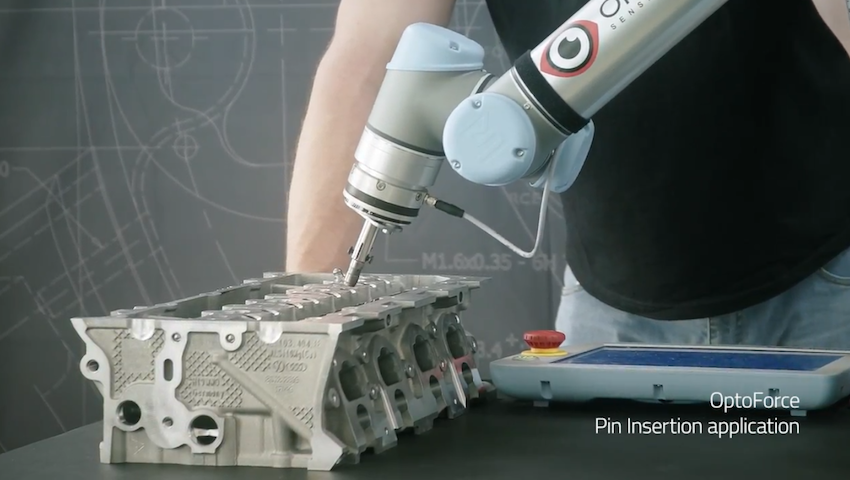

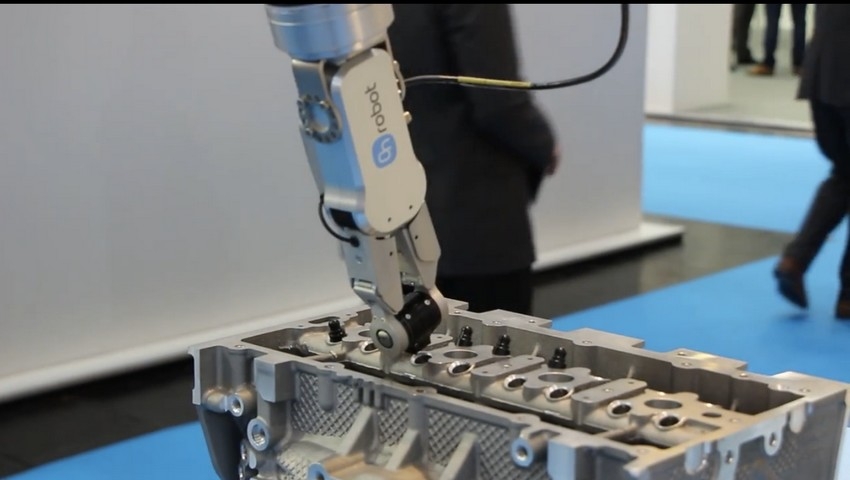

Inserting, Mounting, Positioning, Screwdriving, Nutdriving

When automating assembly operations with one or more collaborative robot applications you increase production speed and quality while lowering your costs. It can run safely next to your employees and take over repetitive tasks to free up your staff for more value-adding work. Handling even small and irregular items, our solutions can help you optimize processes such as screwdriving, mounting, positioning and more. The versality is remarkable, and with easy redeployment, our solutions provide massive value for businesses with a high mix/low volume production.

|

How to Grow your Business with Collaborative Applications

With the dawn of smarter, more adaptive tooling, robots can now function with greater speed, strength, safety and precision, accomplishing a wide range of tasks, while maximizing ROI. Learn more on how you can enable faster production at lower costs by downloading our free eBook.

|

|