5 reasons your competitors are reshoring production

Manufacturers in the EU and the US are moving production closer to home. One reason is supply chain concerns, but they are reaping other benefits as well. Find out if they know something you don’t.

Is local the new global?

The 2018-19 trade war between the United States and China ignited an interest in moving production closer to home for companies based in Western countries. The pandemic stoked the flame, and geopolitical unrest in the EU and renewed political concern about trade relations with China have fueled the fire further.

72 % of organisations are now looking at onshoring or nearshoring their production in the next 12-18 months. And an estimated 1,800 companies reshored at least a part of their production to the U.S. in 2022.

In other words, your competitors are changing tack. Are you keeping up? And should you?

Here are the main drivers for reshoring or nearshoring production.

5 main drivers for reshoring or nearshoring production

1. Domestic production enhances supply chain control.

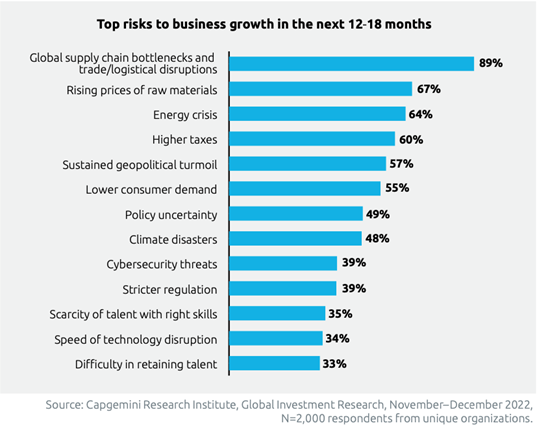

Recent years have seen major disruptions to global supply chains, and concerns about this is the number one driver behind reshoring and nearshoring production to the EU and US.

89 % of executives view supply chain disruptions as the main risk faced by their company, and this is also the area in which organizations are planning to invest most strongly.

2. The cost of global production is increasing

The primary reason for offshoring production to Asia – and to China in particular – was to save on production costs. However, labour costs in China have grown by as much as 25 % in recent years, and the minimum wage is set to increase by 13 % per annum.

This, coupled with the costly risk of supply chain disruptions, has caused many European and American manufacturers to consider moving production closer to home.

In fact, even Chinese manufacturers are pulling out of China!

Some are moving production to Southeast Asian countries such as India, Malaysia and Indonesia where labour is still relatively cheap. Others are investing in production facilities in Mexico and Eastern European countries to bring production closer to consumers in Europe and the US.

3. Reshoring production speeds up time to market

Producing goods closer to home means you can speed up time to market. The logistics are simpler when the entire value chain is located in the same country or region, and you don’t have to wait months for a container ship to deliver your wares.

With no time zone gaps, it is easier for everyone to communicate efficiently, enabling faster problem solving and quick decision making.

4. It enables better production management

Environmental concerns have increased demand for sustainable manufacturing and more durable products of higher quality. Bringing production back to developed countries improves access to skilled labour and makes it easier to track product quality and meet legal and environmental standards.

And let’s not underestimate the brand value to Western consumers of a product “Made in the US” or “Made in the EU”.

5. Technological advances cut production costs

One simple reason for reshoring production is that it is now possible to do so and stay competitive thanks to robotic factory automation.

Despite the steep initial cost of deploying robotic applications, an American study estimates that technological advances in robotic factory automation have cut labour costs by more than 20 % compared to manual operation.

Robotic applications increase productivity and quality consistency, and reduce the production time and the risk – and cost – of personnel injuries.

And with the introduction of OnRobot’s no-code deployment platform, D:PLOY, the deployment costs are cut to a level where robotic automation is attainable for even small and medium-sized manufacturers.

How D:PLOY cuts automation costs

D:PLOY empowers people with no programming experience to deploy and redeploy robotic applications in a fraction of the time it takes a professional programmer to do the job with traditional programming. All they need is the ability to operate an app on their phone. Using D:PLOY is that intuitive.

Not only can you deploy entire robotic applications on site at the factory in a few days – as opposed to weeks or months with traditional programming. You can redeploy the applications for new products, positions and patterns in a few hours. This cuts the ongoing cost of robotic automation:

- You don’t have to hire trained programmers

- You can quickly train operators to manage redeployments

- You can start earning back the investment in robotic hardware in a matter of weeks.

Together, the improved supply chain control, enhanced production management and ease of automation and the rising labour costs in China make a strong business case for bringing back production to developed economies.

Terms you should know

- Reshoring: Returning the production to the company’s country of origin. Also known as inshoring, onshoring and backshoring.

- Nearshoring: Moving production closer to home, often to a country with a shared border. In the EU, nearshoring to countries within the EU is becoming increasingly common.

- Friendshoring: Moving production to a country that shares political values with the company’s country of origin. Also known as allyshoring, this type of -shoring is often encouraged or enforced by domestic governments.

- Offshoring: Moving production to developing countries to save on labour costs.

- China+1 strategy: A type of friendshoring, where companies reduce reliance on China by sourcing from China plus another country in the ASEAN region with more Western-friendly relations, e.g. Vietnam and Indonesia or – for more high-end production – Japan and South Korea.

Dive deeper:

1. ASEAN briefing: Exploring friendshoring: Shifting operations in Asia and China+1. https://www.aseanbriefing.com/news/exploring-friendshoring-shifting-operations-in-asia-and-china1/

2. Scotsman Guide: Reshoring may fuel a long-term industrial boom. https://www.scotsmanguide.com/commercial/reshoring-may-trigger-a-long-term-industrial-boom/

3. Technavio: Industrial robots in the United States to cut labor costs. https://blog.technavio.org/blog/industrial-robots-united-states-cut-labor-costs-21-2020

4. International Journal of Production Economics: Automation and off(re)shoring: A meta-regression analysis. https://www.sciencedirect.com/science/article/pii/S0925527323002128#sec4

4. Cap Gemini Research Institute: Advancing through headwinds: Where are organizations heading? https://prod.ucwe.capgemini.com/wp-content/uploads/2023/01/Final-Web-Version-Report-Davos-2023.pdf

6. South China Morning Post: Chinese companies are moving supply chains out of China to manage risks, with Indonesia, Malaysia and Indonesia benefitting.https://www.scmp.com/news/asia/south-asia/article/3218025/chinese-companies-are-moving-supply-chains-out-china-manage-risks-india-malaysia-and-indonesia

|

How to Grow your Business with Collaborative Applications

With the dawn of smarter, more adaptive tooling, robots can now function with greater speed, strength, safety and precision, accomplishing a wide range of tasks, while maximizing ROI. Learn more on how you can enable faster production at lower costs by downloading our free eBook.

GET THE FREE eBOOK

|

|