Top considerations for automating your palletizing applications

If you have not started automating your palletizing tasks in 2023, you are falling behind. Palletizing is among the most widely automated industrial applications, according to McKinsey’s 2022 survey, and the palletizing automation market is growing at a compound annual growth rate (CAGR) of 4.2 %. This is hardly surprising, as the heavy, repetitive work of loading pallets is perfectly suited for robotic automation.

Not only can robots load a pallet faster and more accurately than humans, but it also spares them from heavy lifting, resulting in lower risks of work-related injuries. And as robots have become smaller, safer, and much faster to deploy, robotic palletizing automation is now well within reach of most small and medium-sized (SME) manufacturers.

If you are an SME, then this article will teach you how to see faster returns on your robotic investment and guide you in selecting the right robotic palletizing application.

1. Ensure return on investment when automating palletizing

The high initial cost of robotic palletizing automation and the risk of not getting a full return on the investment discourages many small and medium-sized manufacturers. But with the right automation strategy you can ensure a faster return on your investment:

Automate in stages

With collaborative robots, you do not have to automate all your palletizing stations in one go. Start with one palletizing work cell. Adjust and optimize that application and apply what you learn when automating the next work cell. This not only reduces the initial investment, but also enables you to deploy the next applications faster and more accurately.

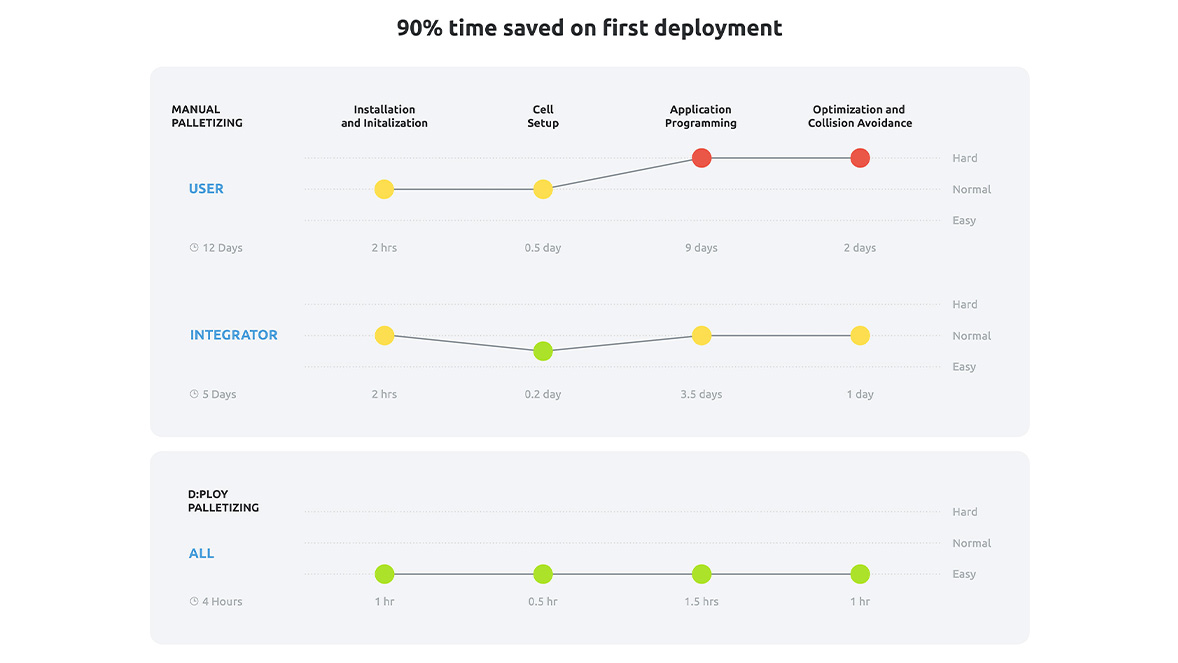

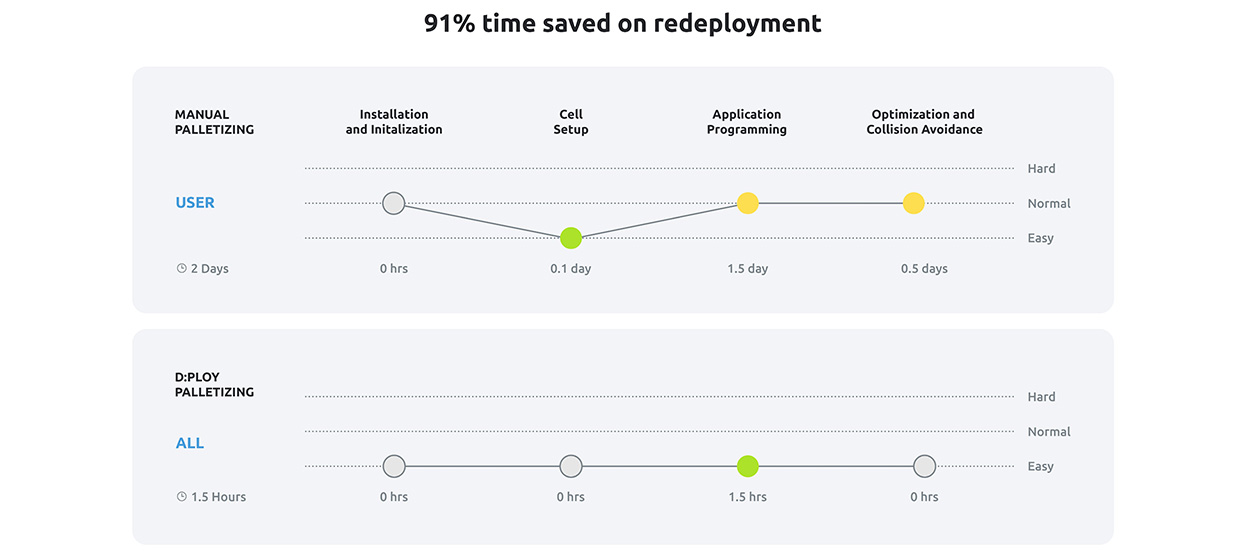

Cut down deployment time by up to 90 % with D:PLOY

The deployment time and the cost of internal training and external programming specialists make up a large part of the initial cost of a robotic palletizing application. With OnRobot’s no-code automation platform, D:PLOY, your robotic palletizing application can be up and running in as little as four hours.

The platform takes care of the programming and has an intuitive, app-like interface, so even people with zero programming experience can easily deploy a palletizing application in less than a day.

And if your production requirements change, you can quickly introduce new boxes or containers, pallet sizes and palletizing patterns.

D:PLOY Palletizing works with many leading collaborative and light industrial robot arms and offers unparalleled flexibility for changeovers, cell layout and more.

Involve your palletizing operators

The operators currently handling the manual palletizing know the ins and outs of the job and can provide important input to the application. By involving them in the planning and deployment process, you increase the likelihood of organizational buy-in, which is the number one prerequisite for achieving a successful implementation of the palletizing automation and securing ROI. And with the D:PLOY’s automatic programming and intuitive, app-like interface, operators will require very little training and upskilling to be able to deploy and redeploy your palletizing applications as needed.

2. What type of robotic palletizing automation do you need?

To determine which robotic palletizing solution is the right one for your production line, you need to ask yourself:

- What is your required production throughput per day?

- How consistent is the size, shape, and weight of the production units?

- How consistent is the pallet size and pattern?

- How much floor space is available for the palletizing application?

- How much time are you willing to spend on deployment and redeployment?

- What are your plans for up- or downscaling production?

- What is your budget?

Determine your pick-up strategy

Palletizing is one of many robotic pick and place applications defined by the robot and gripper picking up an item and placing it correctly somewhere else.

For the robot and gripper to be able to pick up the products consistently, either the items must be presented in a fixed, repeatable position such as at the end of a slide or conveyor belt, or the robot can use presence sensors or cameras to detect items on a moving conveyor belt.

If you currently have a manual palletizing setup, a collaborative robot can take the place of an operator in the product flow, allowing the operator to perform less strenuous tasks.

A light industrial robot arm, on the other hand, will need fencing and other safety measures, which means you will have to adapt your palletizing setup to a larger extent.

Choose the right robot arm for palletizing applications

When choosing the robot arm for your palletizing application, the three main parameters to consider are:

Payload: Can the robot and gripper lift the palletized items – even at its full extension?

Reach capabilities: Can the robot reach the far end of the pallet and the top of the fully loaded pallet? Or does your application require a lift for the robot to place boxes in the top layers?

Speed: Is the robot fast enough to meet your throughput requirements – and how fast can you operate it safely?

For the low-volume, high-mix manufacturing characteristic of most SMEs, this leaves you with a choice between light industrial and collaborative robots.

Choose the end effectors best suited to your palletizing objects

The end of arm tools or grippers are determined by the nature of the production items to be palletized:

- What is the shape, weight, and size of the items?

- Is it one product or a mixture of products?

- What surface material do the items have – cardboard, metal, plastic?

See which grippers we recommend for palletizing applications

3. Fast automatic programming with D:PLOY

With the launch of OnRobot’s no-code deployment platform D:PLOY, the programming process has been automated, leaving you free to choose the robotic application best suited to your production needs.

That means you can now deploy and redeploy both light industrial and collaborative robotic palletizing applications in less than a day without any programming experience.

Sources:

1. Ajewole, Femi, Ani Kelkar, Dylan Moore, Emily Shao, and Manju Thirtha: Unlocking the industrial potential of robotics and automation. McKinsey & Company, 6 January 2023. https://www.mckinsey.com/industries/industrials-and-electronics/our-insights/unlocking-the-industrial-potential-of-robotics-and-automation#/

2.Fortune Business Insights: Palletizer Market Size, Share & COVID-19 Impact Analysis (…), 2021-2028. October, 2021. https://www.fortunebusinessinsights.com/palletizer-market-104445

|

Jak rozwijać firmę za pomocą aplikacji współpracujących

Dzięki inteligentniejszym narzędziom o większych możliwościach dostosowania, roboty mogą obecnie pracować przy większej prędkości, sile i dokładności oraz zwiększonemu bezpieczeństwu, wykonując szeroki zakres zadań przy jednoczesnym maksymalizowaniu zwrotu z inwestycji. Pobierz nasz bezpłatny e-book i sprawdź, jak umożliwić szybszą produkcję przy niższych kosztach.

POBIERZ BEZPŁATNY eBOOK

|

|