MATERIAL HANDLING

MATERIAL HANDLING

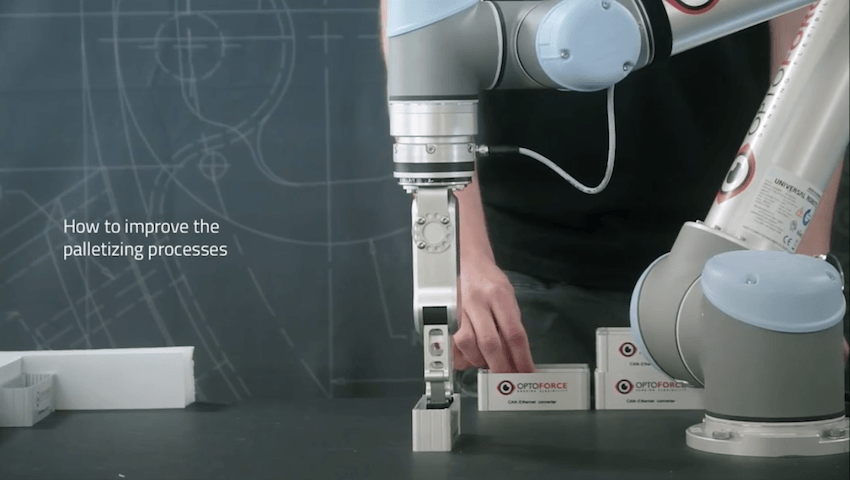

Transferring, Sorting, Packaging, Palletizing

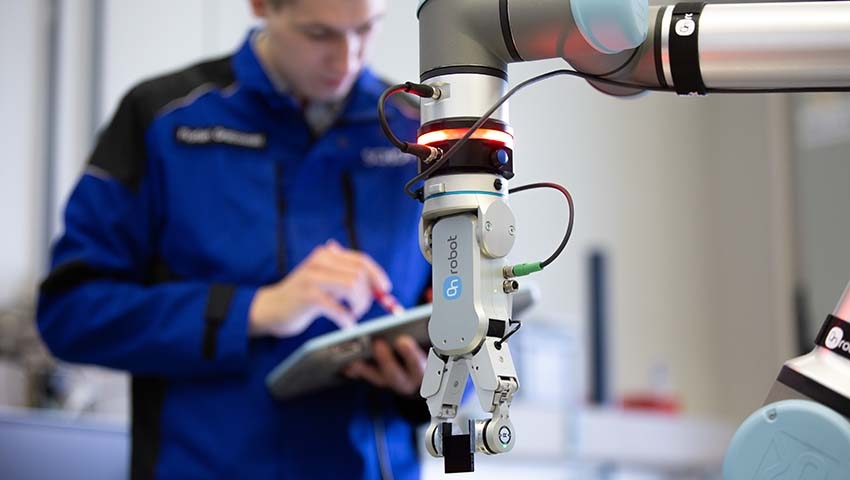

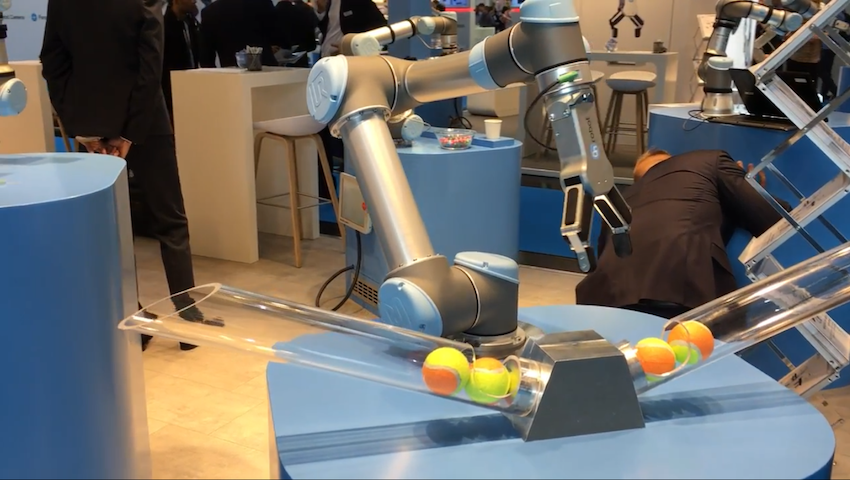

It makes great sense to automate material handling processes, if you want to reduce physically straining work or increase productivity without having to worry about recurring labour shortage. In material handling applications, items are moved from one position to another – often referred to as “Pick and Place" applications. Depending on your needs, the robot can work beside your employees, transferring or sorting items, or it can carry out packaging, palletizing or other processes. Whether it requires sensitivity, flexibility or strength, you will get precision handling hour after hour.

|

How to Grow your Business with Collaborative Applications

With the dawn of smarter, more adaptive tooling, robots can now function with greater speed, strength, safety and precision, accomplishing a wide range of tasks, while maximizing ROI. Learn more on how you can enable faster production at lower costs by downloading our free eBook.

|

|