Accelerate your sustainability efforts with robotic automation

Robotic automation is a strong key player that accelerates your transition towards sustainable production and increases the likelihood of long-term organizational success.

Why sustainable manufacturing is important

Are you still viewing ESG legislation and the transition towards green manufacturing as a potential threat? Then you could be leaving golden growth opportunities on the ground.

Today, traditional financial metrics are only one factor in the long-term value of your company. Of course, you need your business to be financially sustainable to attract investors and stay competitive. But according to Ernst&Young, investors are looking increasingly at manufacturers’ progress on ESG sustainability factors to determine their long-term organizational success.

Not just because acting responsibly on environmental, social and governance (ESG) issues is the right thing to do, but because sustainable production is crucial to achieving customer loyalty, access to capital markets and a social license to operate, according to a McKinsey report:

“A strong ESG proposition helps companies tap new markets and expand into existing ones. When governing authorities trust corporate actors, they are more likely to award them the access, approvals, and licenses that afford fresh opportunities for growth,” the report finds.

With the aid of robotic automation, you can accelerate your progress towards sustainable manufacturing and increase the long-term organizational success of your business. Here is how:

How robotic automation accelerates environmental sustainability

Environmental sustainability criteria include your company’s energy consumption, its carbon and other emissions, and the waste it discharges, the resources it needs, and the consequences for the environment and other living beings.

Increase operational efficiency

Robotic applications provide high repeatability in the production, increasing the consistency and accuracy of your product. This means you can cut your company’s wastage and energy consumption, as fewer products need to be scrapped and reproduced.

Minimize the negative environmental impact

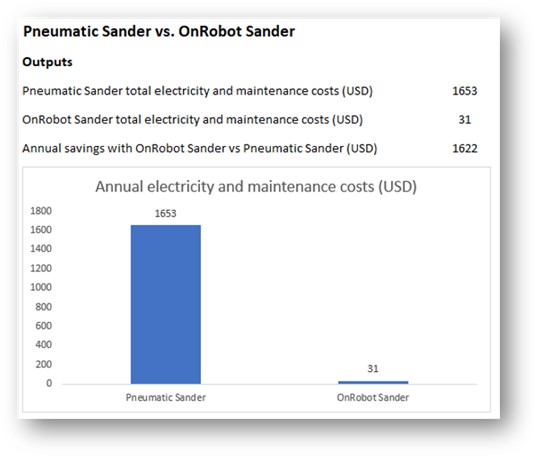

With robotic applications, you can easily choose electricity-based tools over pneumatic (compressed air) tools. Pneumatic tools consume vastly more energy as demonstrated in the comparison between the electric vs. the pneumatic sander below:

Electricity-based production saves energy as well as money, and you can use renewable energy sources such as wind power and solar panels to power your production, cutting down on emissions as well.

How robotic manufacturing boosts social sustainability

Social criteria encompass your company’s relationships with stakeholders, including labor relations, diversity and inclusion, and your reputation in the communities where you do business.

Retain good relationships with customers

With robotic applications on your production line, you can shorten the lead time, ensure a consistent quality of the product and deliver it on time, ensuring customer satisfaction and loyalty and a good reputation as a supplier.

Improve working conditions

Robots are perfect for the heavy, hazardous and/or repetitive tasks that are most likely to cause work-related injuries to human operators. Automating those tasks on the production line allows your human workers to perform safer and more value-adding tasks.

Upskill labourers

Part of implementing robotic automation is training and upskilling workers to perform more value-adding tasks such as redeploying a robot for new applications.

Provide new and better job opportunities

Popular belief has it that robots take the jobs of humans. But according to a European study on the impact of robots and labour market, robotic automation has a positive impact on employment, especially in countries with low labour costs, which suggests that the same dynamic would apply to most Asian economies.

Collaborative robots have enabled manufacturers to use robotic applications as an addition to rather than a substitute for human workers, and robotic automation also creates new, more rewarding jobs for humans, the study finds.

How robotic automation strengthens governance in manufacturing

Governance criteria include the internal system of practices, controls, and procedures your company adopts in order to govern itself, make effective decisions, comply with the law, and meet the needs of external stakeholders.

Enable compliance with consistency in the production

We have yet to invent a robot that can handle your ESG documentation, but by automating your production, you can achieve consistent production quality, improve workplace safety and reduce energy consumption, which makes it easier to comply with the various international and local sustainability regulations and standards.

Build sustainable business resilience with no-code robotic automation

Flexibility is key to remaining competitive in a rapidly changing commercial and political landscape. You need to constantly adapt your production, both in terms of regulations, throughput and products, to meet changing stakeholder demands without losing control of quality and financial, social and environmental costs.

With OnRobot’s no-code deployment platform, D:PLOY, deploying robotic applications and reaping the ESG benefits of factory automation has never been faster. D:PLOY makes robotic automation a highly flexible option for any low-volume, high-mix manufacturer as the platform enables you to deploy your first robotic application in a matter of days and redeploy it for other applications in just a few hours.

Financial sustainability

D:PLOY automates the programming of robotic applications, reducing the time spent on deployment of each robotic application by up to 90 %.

In other words, deployments and redeployments that would take a professional system integrator days or even weeks with conventional programming, can be done in a few hours by anyone – no programming experience required.

This reduces the need for (and cost of) external service providers and enables a faster return on investment.

Environmental sustainability

By automating faster, you can obtain the environmental sustainability advantages of robotic automation that much sooner, and as the deployment process takes only a tenth of the time of conventional automation, the deployment consumes less energy.

Social sustainability

D:PLOY’s intuitive, app-like interface means that your operators can easily learn to deploy and redeploy robotic applications with little training required. This quickly provides them with more value-adding jobs and leaves them less prone to work-related injuries compared to manual tasks such as palletizing, packaging and machine tending.

Governance

With D:PLOY’s process and cycle data at your fingertips, you can easily streamline production practices, document compliance with procedures and provide transparency into the company’s manufacturing activities for stakeholders.

Learn how you can benefit from D:PLOY

Quick Facts:

What is ESG in manufacturing?

ESG is short for Environment, Social and Governance and is a more stakeholder-centric approach to manufacturing and doing business.

Where is ESG reporting mandatory?

Extensive ESG reporting is mandatory in the EU for larger manufacturers. The US is planning similar legislation, while rules and requirements for ESG reporting in Asia vary from country to country. E.g., Japan is introducing mandatory reporting, whereas Singapore and Thailand require reporting on a “comply or explain” basis. (Source: Tokyo Institute of Technology and Mazars, 2022)

The European ESG requirements will affect all companies in the larger manufacturers’ value chain, regardless of size, as well as non-EU manufacturers that generate a net turnover of more than €150m in the EU.

Sources:

1. Bachmann, R. et al, 2022: The impact of robots on labour market transitions in Europe.

2. EY, 2022: 5 ways manufacturing companies can tackle ESG now.

[https://www.ey.com/en_ca/advanced-manufacturing/5-ways-manufacturing-companies-can-tackle-esg-now]

3. Tokyo Institute of Technology and Mazars, 2022: Sustainability reporting in Asia: Are the EU’s initiatives the benchmark for ESG disclosure in the region? [https://www.mazars.sg/content/download/1114680/57559642/version/1/file/Sustainability-reporting-in-Asia-Full-publication-2022.pdf]

4. McKinsey, 2019: 5 ways ESG creates value, McKinsey Quarterly, November 2019.

[https://www.mckinsey.com/~/media/McKinsey/Business%20Functions/Strategy%20and%20Corporate%20Finance/Our%20Insights/Five%20ways%20that%20ESG%20creates%20value/Five-ways-that-ESG-creates-value.ashx]

|

So erweitern Sie Ihr Geschäft mit kollaborativen Anwendungen

Mit dem Aufkommen intelligenterer, anpassungsfähigeren Werkzeuge können Roboter nun mit höherer Geschwindigkeit, Stärke, Sicherheit und Präzision arbeiten und bei Maximierung des ROI eine Vielzahl an Aufgaben erledigen. Erfahren Sie mehr darüber, wie Sie die Produktion bei geringeren Kosten beschleunigen können, indem Sie sich unser kostenloses eBook herunterladen.

KOSTENLOSES eBOOK ANFORDERN

|

|