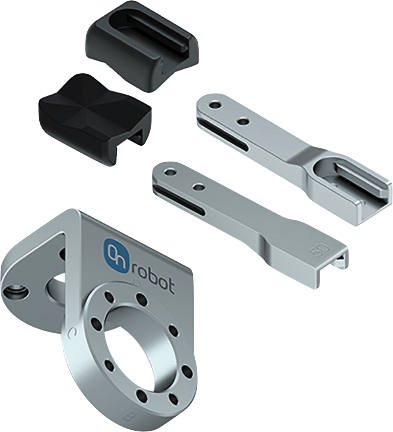

See all accessories available from OnRobot to optimize your collaborative robot application.

All our grippers, force/torque sensors and tool changers are compatible with robots from Doosan, TM Robot, Yaskawa, Universal Robots, KUKA, Fanuc, Kawasaki Robotics, Hanwha,Nachi, Denso, ABB and Kassow. Because our products are compatible with the major robot brands, you can easily get started with maximizing utilization of your robots. If your robot is from another brand, that doesn''t mean our grippers won''t be compatible with it. Contact us to discuss which solution seems most feasible for you.

Collaborative robots, also known as “cobots”, and light industrial robots are widespread today because of the rise of versatile tools, such as robot arm grippers, sensors, and quick changers. By combining your robot with the right end effector, you empower its ability to handle complex processes in safe collaboration with human employees. Collaborative technologies are known for bringing business benefits to small and medium companies.