Optimize your throughput and boost flexibility with a powerful pneumatic vacuum gripper, designed for high-mix applications.

View product

Certified food-grade soft robot gripper for handling food, beverage, cosmetics, pharmaceutical and other delicate items.

View product

A flexible, large-stroke 3-Finger Gripper ideal for a wide range of objects and shapes in machine-tending applications such as CNC lathe machine.

View product

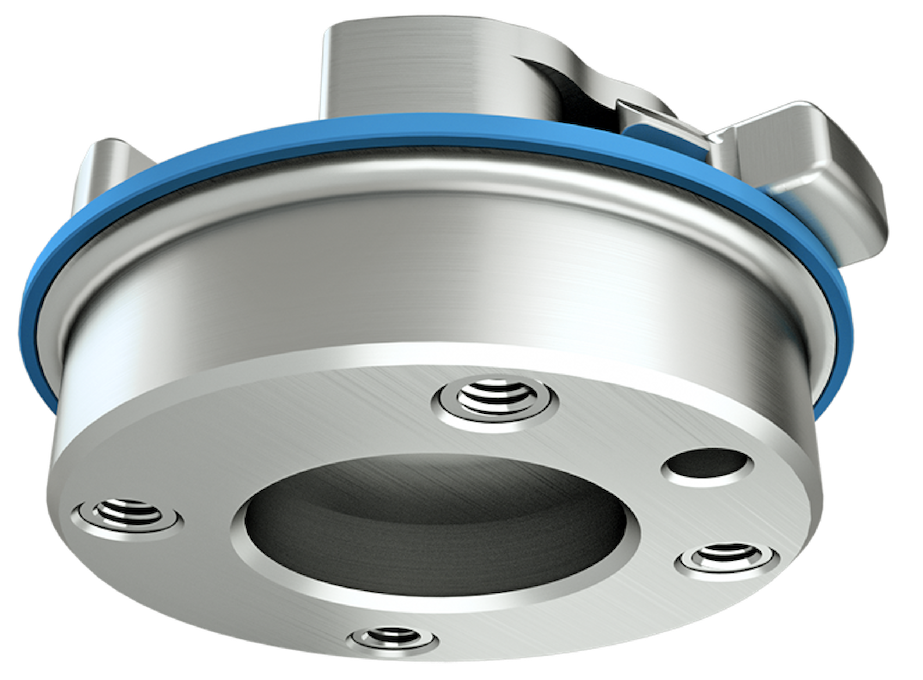

OnRobot's Dual Quick Changer enables you to use our end-of-arm tools together in a single cycle - Improve productivity by 50% or more.

View product

Flexible and compact plug-and-play gecko gripper designed to fit even tight spaces. Fast deployment with lower operating costs.

View product

Accurate force and torque measurements with 6 axis force torque sensor for various applications. Designed to fit most of the industrial robot arms.

View product

Long-stroke, high-payload robot elevator for versatile 7th axis. Ensures precise positioning in palletizing and manufacturing applications.

View product

Magnetic gripper for material handling, assembly and machine tending applications in manufacturing, automotive and aerospace environments.

View product

Flexible and adaptable 2.5D robot vision system, OnRobot eyes are deployed in many collaborative applications from sorting, CNC machine tending and more.

View product

Complete electric random orbital sander solution can be deployed for almost any automated finishing application, from sanding and buffing to polishing and cleaning.

View product

This smart screwdriver easily automates multiple screwdriving processes with no downtime for manual changeovers. It gets the job done right, consistently and faster, with precise torque control and intelligent error detection

View product

The RG2 gripper is a flexible collaborative 2 finger gripper with wide strokes. Fast deployment and easy customization for a wide range of applications.

View product

The RG6 is a flexible collaborative gripper with a larger reach and a built-in OnRobot Quick Changer that broadens the scope of applications you can automate

View product

VG10 is a flexible and adjustable EoAT dual suction gripper designed for collaborative robot applications from machine tending to material handling.

View product

The VGC10 is perfectly suited for tight spaces and smaller robot arms. Quick and easy to redeploy, with unlimited customization for nearly any application.

View product

Electric vacuum gripper ideal for heavy-duty packaging and palletizing applications with payload up to 20kg.

View product

Built to handle larger and heavier parts, the heavy-duty gripper 3FG25 is ideal for CNC Machine Tending, Material Handling and Assembly tasks.

View product

Parallel gripper for collaborative and light industrial robots, helps you automate pick and place, machine tending and assembly tasks.

View product

The 2FGP20 electric gripper is ideal for palletizing applications offering a wide stroke and customizable arms to handle different products.

View product

2FG14 - High-payload parallel gripper designed for CNC machine tending applications

View product